● Simultaneous surface/bottom double-sided inspection

● No time loss

● Full speed and full performance

● Multiple configuration combinations can be selected

-AOI AOI/AOI THT/THT AOI/THT THT

Advanced high-speed and high-precision detection and measurement technology

-8/10 Projection 3-layer RGB

-3D and 2D synchronous detection algorithm

-Far center lens ensures high-precision detection

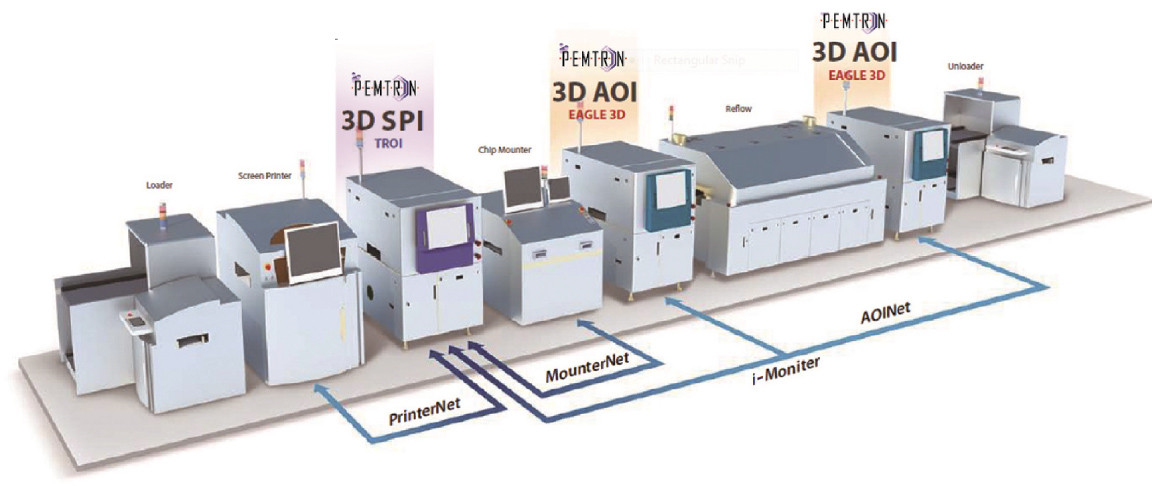

● Lean and efficient whole line control capability

● The best 3D imaging quality in the industry ● The most innovative and flexible solution in the industry

Unique 3D inspection technology

● 4-way side camera (optional)

-Can detect the internal area of the connector

-Utilize existing algorithms to facilitate teaching

Simple and clear user interface

-The same convenient UI interface as AOI makes it easy for all customers to use

-Simultaneously display all results of double-sided detection

-AOI or TH detection can be set on both the surface and bottom

Check the data automation system

-Establish a closed-loop system with the printing machine

-3-point comparison system

-Establish a closed-loop system with the SMT machine

-One software can monitor up to 12 devices

-BadMark data sharing and automatic patch optimization

-Using AO | test data, automatically compensate for patch coordinates and optimize them automatically

Process statistical control

Pemtron's SPC can collect and analyze test results, and display them to users at a glance. Flexible and versatile SQL can provide users with various reports and results that meet their needs.

The server option can centralize the online monitoring results of multiple devices and reflect the production status of the production line in real-time in SPC.

Technical Parameter

Please leave a message below before downloading the materials. Thank you.