TROI 8800 CI Series

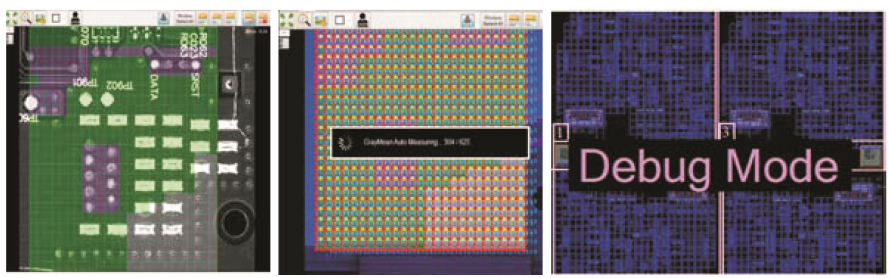

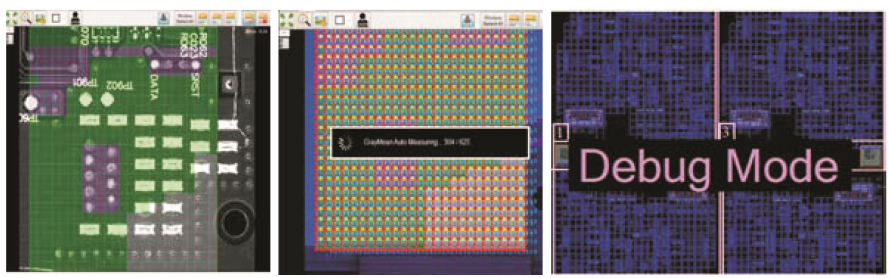

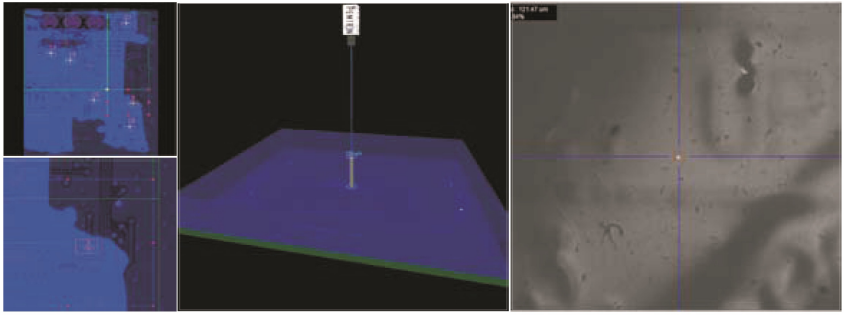

Automated Teaching&OptimizationUsing well coated PCB templates, the system automatically identifies and sets reasonable parameters, and uses them as standard values for actual production

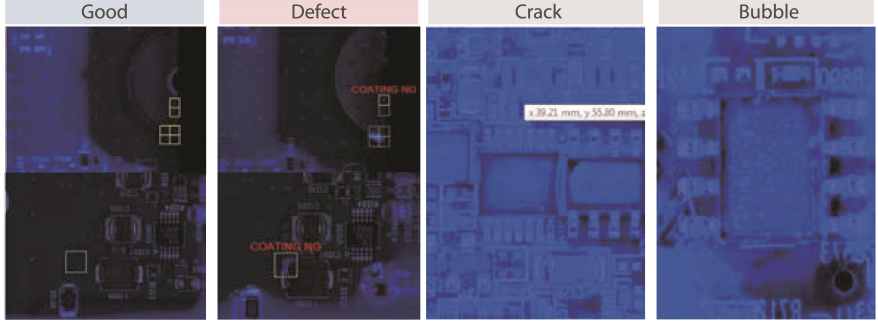

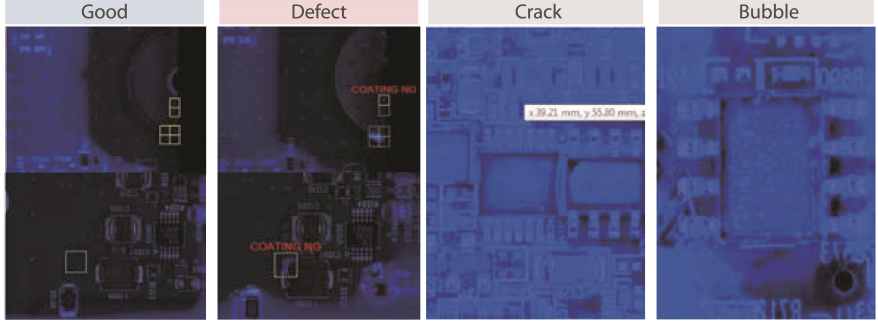

Reliable coating testing

Simple programming and fast testing

Can accurately detect defects such as cracks, dirt, splashes, bubbles, coating thickness, etc

Closed loop function "SPI A0l CI"

Real time monitoring and quality control solution PEMTRON detection result automatic matching system is used to provide intuitive monitoring of each production process

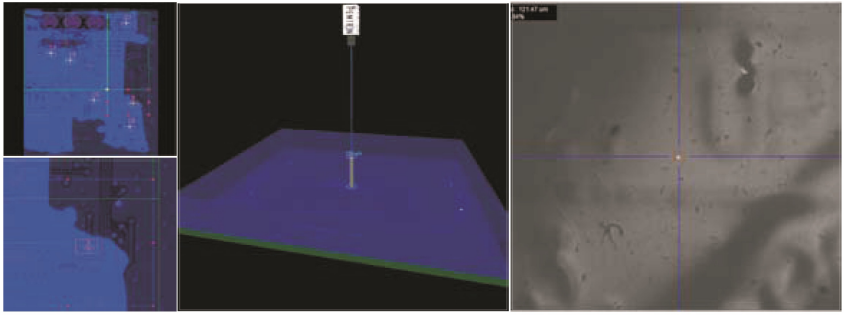

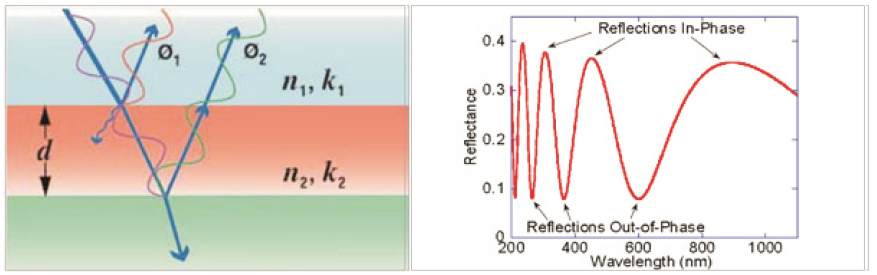

Thickness measurement

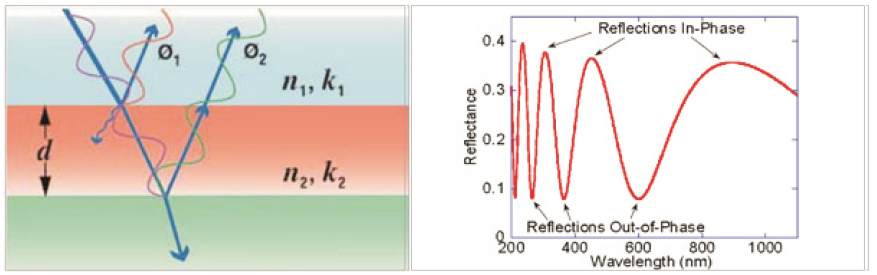

Using laser to measure the thickness of coated surfaces based on its reflection principle

When the light beam reaches the interface between two different materials, it will be partially reflected. The wave like nature of light causes interference between reflections from multiple interfaces, resulting in oscillations in the wavelength spectrum of the reflected light. Based on the interference pattern generated, we determined the distance between different materials, which is the coating thickness we want to test.

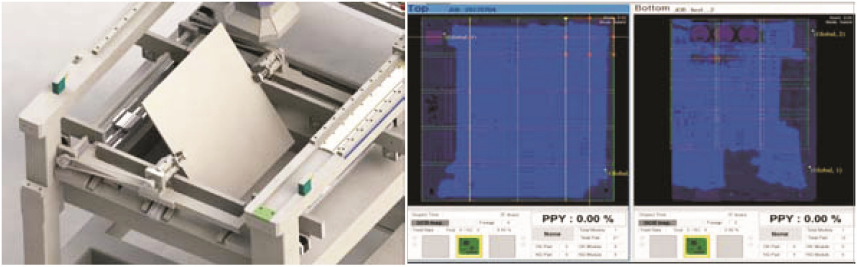

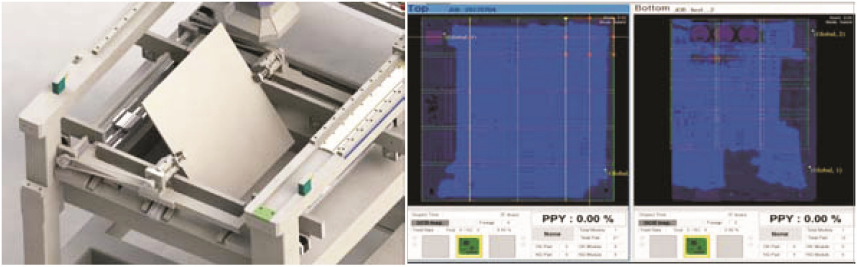

The flip module can be used for double-sided detection

The flip module can be used for double-sided detection

Simple and fast PCB automatic flipping, capable of detecting both sides without leaving the board

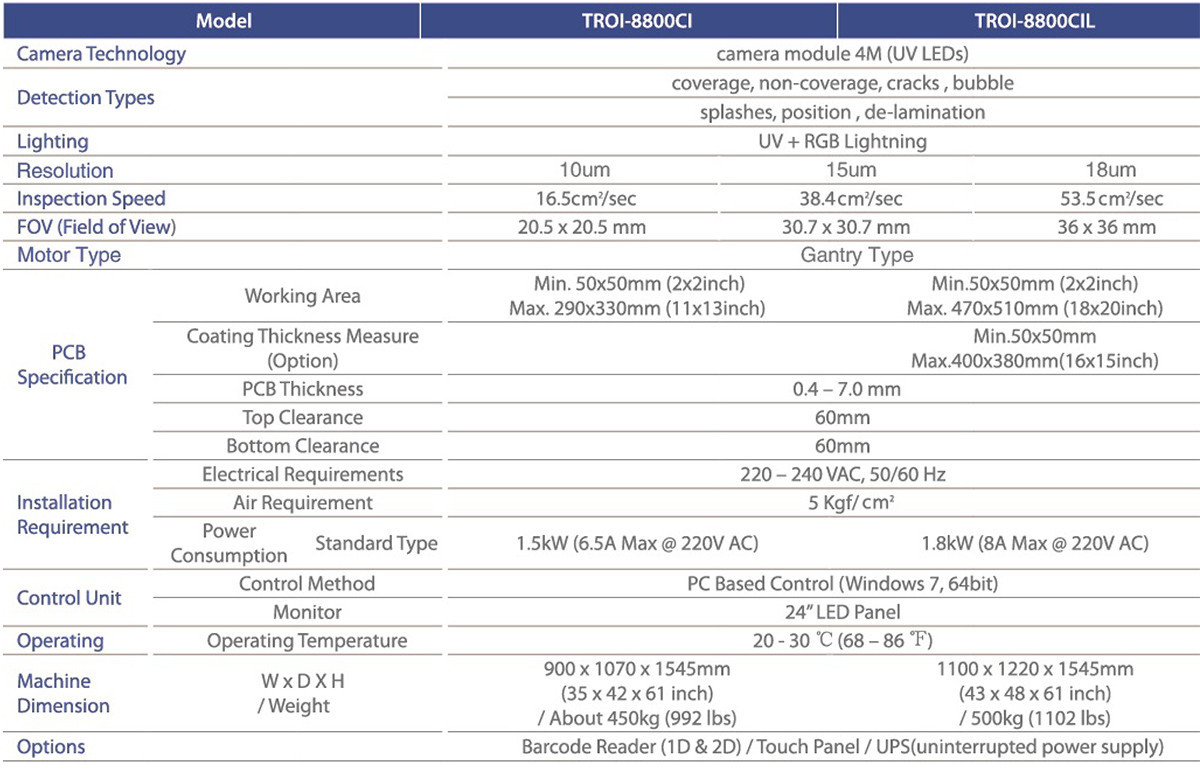

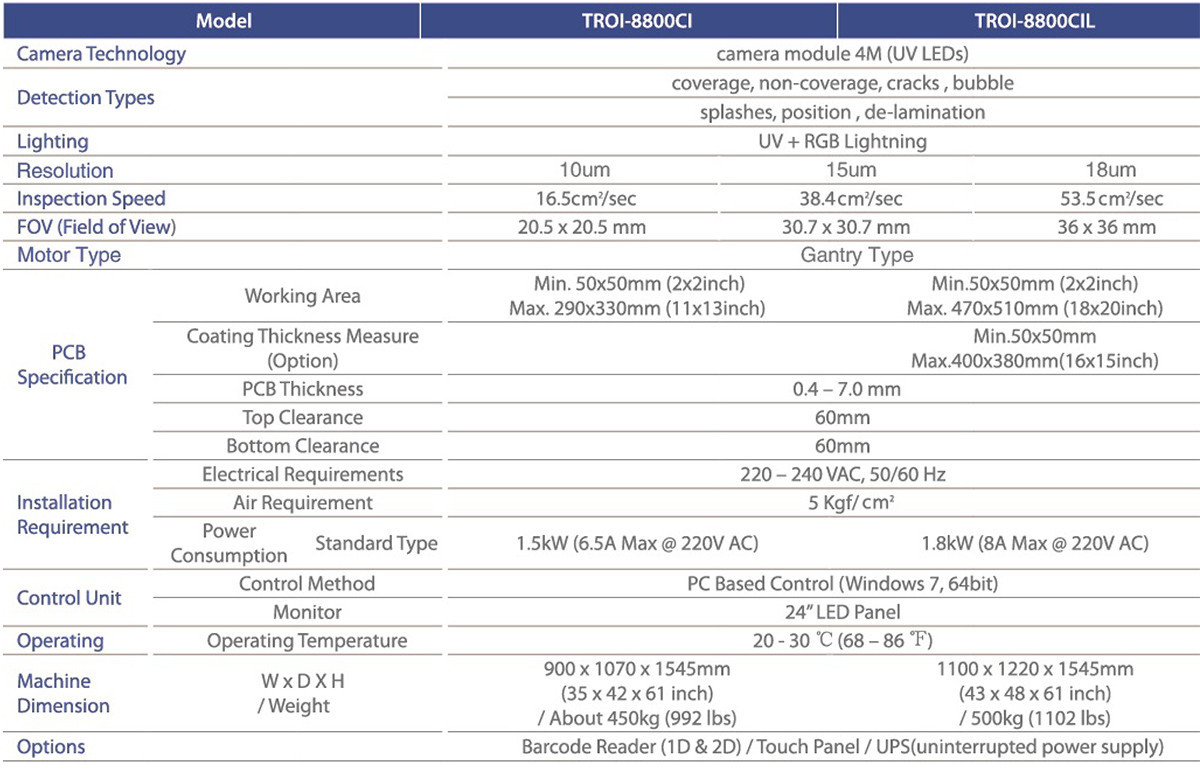

Parameter specifications

Parameter specifications

Application Scenario:

Data download:

Please leave a message below before downloading the materials. Thank you.

Online Message: