Time:2022-12-06 Browse:5635

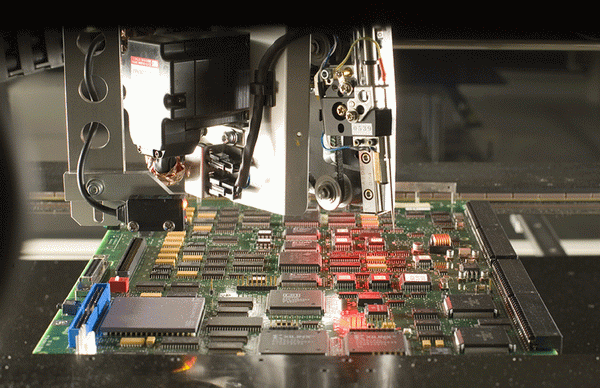

AOI detection is a part of the visual inspection equipment in the industrial machine vision industry chain. In the downstream application field of industrial machine vision, AOI detection is widely used in electronic components such as PCB printed circuit boards, flat panel displays, and semiconductors. It is an important component in the current production process of PCB printed circuit boards and integrated circuits.

2. AOI detection has entered the stage of intelligent development

The AOI detection industry in China started in the 1980s and has roughly gone through four stages, from the blank period in 1985 to the intelligent stage so far, from manual visual inspection to the continuous application of 3D AOI detection technology. With the development of SMT assembly towards refinement and refinement, AOI detection equipment has broad application prospects.

Analysis of the Development History of AOI Testing

Blank period (1985 1995): China introduced the first SMT machine, and AOI testing entered the initial stage

Development period (1996-2003): Localization of AOI testing equipment for enterprises mainly focused on Shenzhou Vision

Rapid development period (2004-2010): AOI technology continues to progress, domestic brands begin to collaborate with foreign brands to develop more advanced equipment, and China's AOI testing enters a rapid development period

Intelligent development stage (2011 present): With the continuous application of technologies such as big data, artificial intelligence, and machine learning, AOI detection continues to develop in the opposite direction of intelligence

3. The main downstream application areas of AOI detection in electronic component testing

AOI testing is currently aimed at detecting the wafer appearance, 2D/3D, bumping, and IC packaging of PCB printed circuit boards, solder paste printing, components, solder components, and integrated circuits.

PCB printed circuit board: PCB light board testing, solder paste printing testing, component testing, post weld component testing, etc

Integrated circuits: wafer appearance inspection, 2D/3D inspection, bumping inspection, IC packaging inspection, etc

FPD flat panel display: Mura defect detection, Color Filter detection, PI detection, LC liquid crystal detection, chromaticity, film thickness, optical density detection, LC liquid crystal detection, chromaticity, film thickness, optical density detection

Other industries such as automotive electronic testing, Micro Crack testing, etc

4. Enterprises enter the stage of actively using AOI detection

Enterprises have gone through three stages in using AOI detection devices, namely passive use stage, forced use stage, and active demand use stage. As PCB and FPD manufacturing enterprises gradually deepen their acceptance of AOI detection devices, the penetration rate of AOI detection devices also gradually increases.

Passive use stage:

Based on the freshness of the purchase, I have a preliminary understanding that AOI detection devices have limited understanding of AO detection equipment, and there are difficulties in management and operation, and they are rarely actively used.

Forced use stage:

Due to the increasing quality requirements of customers, many OEM manufacturers have to purchase AOI testing equipment to conduct quality testing on their products in order to obtain orders.

Active use stage:

With the development of technology, SMT assembly is gradually refined and refined, and human eye testing cannot meet the requirements of product quality. As a result, labor costs have increased. In order to save costs and improve quality requirements, enterprises actively use AOI testing equipment.