In 2009, the world first launched an online vacuum reflow soldering system that can achieve cavity free soldering

SMT Highlights:

All SMT systems do not require the use of any tools for maintenance

Catalytic ABS - Thoroughly Purification and Recovery of Flux Gas

Sustainable energy-saving and nitrogen saving technologies

Verified vacuum reflow soldering technology (first introduced globally in 2009)

All areas have independent stepless variable frequency fan control

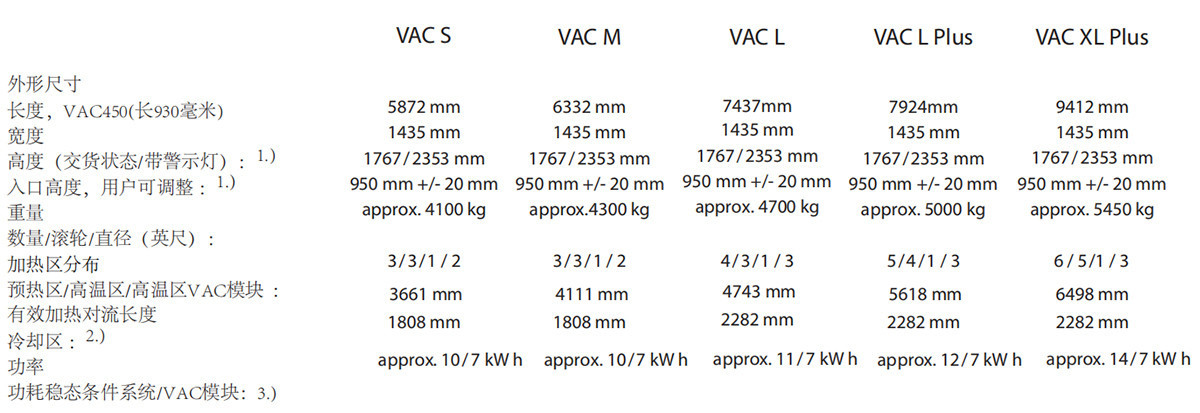

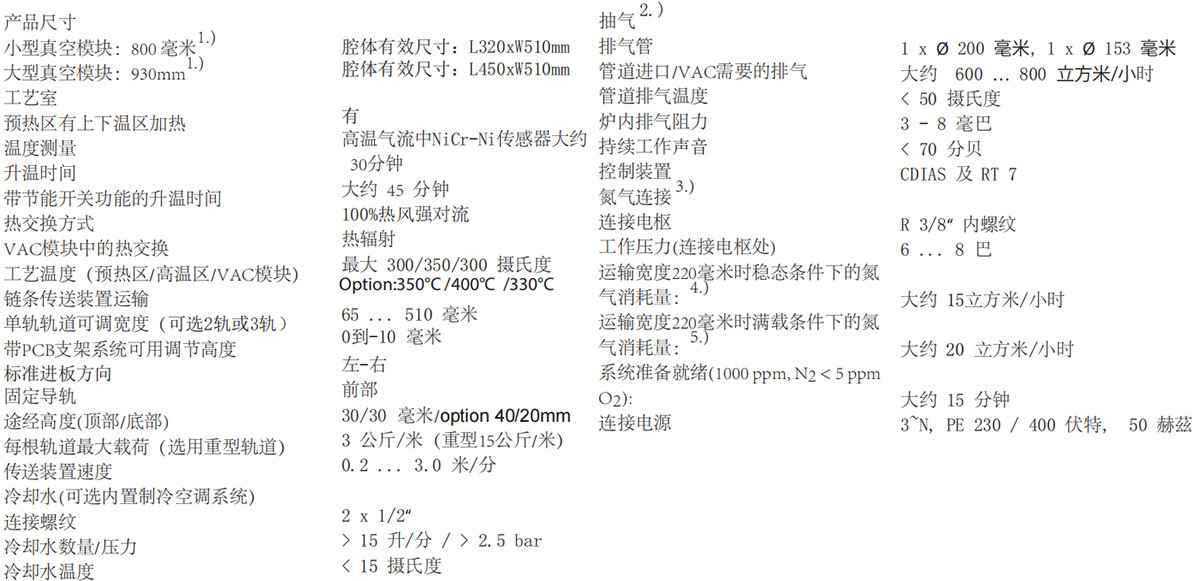

technical data

1.) Standard height: 950 millimeters; Corresponding to the height of the entrance after the change

2.) There can be up to 5 cooling zones. Each cooling zone: 474 millimeters.

3.) The machine is equipped with a chain conveyor, a transport width of 220 millimeters, a fan reduction mechanism, and no other options

Technical data of SMT "VAC S"~SMT "VAC XL Plus"

1. There are differences between dual channel or triple channel

2.) Connect flexible heat-resistant (at least up to 100 degrees Celsius) hoses (SMT available) or pipes. Users must install exhaust emission devices and adjustable flow valves behind the intake sleeve.

3.) Users must install a nitrogen supply with a pressure reducing valve, and it is recommended that the oxygen content of the nitrogen supply be less than 5 ppm

4. 1000 ppm with proportional valve and sleep mode (optional); If it is 100 ppm, it is about 20-30 cubic meters per hour

5.) If it is a PCB (220 x 220 mm), the length spacing of one PCB is 1000 ppm; If it is 500 ppm, it is about 17 cubic meters per hour, and if it is 100 ppm, it is 20-30 cubic meters per hour.

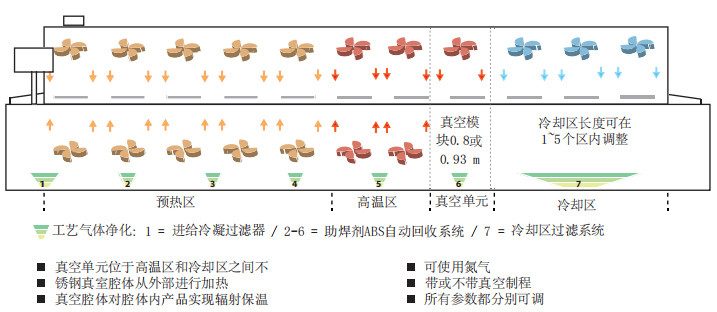

SMT reflow soldering highlights:

Automatic Flux Recycling System ABS:

Molecular sieves can be physically cracked at lower temperatures through the use of molecular sieves

The process of filtering and recycling flux FLUX

Better and cleaner recovery of Flux, keeping the furnace clean,

Lower maintenance and upkeep costs.

Particles coated with precious metals can promote the splitting of long-chain hydrocarbons, resulting in

The machine material ideally decomposes completely into water and carbon dioxide.

Adopting integrated oxygen sensor technology directly installed inside the furnace to detect nitrogen gas

Accurate control and real-time continuous measurement of furnace oxygen values

Lower nitrogen consumption

Easy calibration (can be replaced by customers)

Airtight fan device

Constant hot air volume, adjustable through stepless frequency converter

Sealed maintenance free fan motor with a 10-year warranty

Energy and nitrogen conservation;

Lowest operating costs

Lowest energy and medium consumption

Spare parts and wear parts (e.g. rails, chains, fan motors, heating elements)

Minimum consumption of items

Please leave a message below before downloading the materials. Thank you.